Specifications

high-speed folded rolls-connecting garbage bag making machine

applied to making big linkage bags, and fold the film

Usage:

This machine is applied to making big linkage bags, and fold the film as 3-layer or 4-layer. This machine rewinding bags automatic, without paper-core.

Main Features:

1. Usage: FD Model bag making machine is suitable for making rolls bags.

2. Automatic: it can do one-line production of the following steps: heat sealing and cold cutting, and rotate the bag into a roll.

3. Computer control system: the user can use the monitor control panel on the computer to read technical parameters, set bag length, working speed. It is very convenient.

4. photo cell: photo cell is used for print bag to do one line production.

5. photoelectric control feeding system: this system is used to control film feeding system.

6. Automatic temperature control: It adopts intelligent temperature controller to control the temperature easily.

7. Electric static mover bar: it can treat the static on the film, the finished bags will easily go out and be smooth.

8. Automatic counting system: user can set the numbers of bags by each bundle. The computer will automatically count it. In this way, the user can easily know the production of bags.

9. Alarm system: when the machine finish the quantities of bags, which is set by the user. The alarm system will give alarm sound to reminder the user its near finishing job. Moreover, if the photo cell cannot find the printed mark position, it will also alarm.

10. Alarm sensor to stop machine: the machine should equipped with an sensor, when the operator’s hand close to knife, the machine will stop.

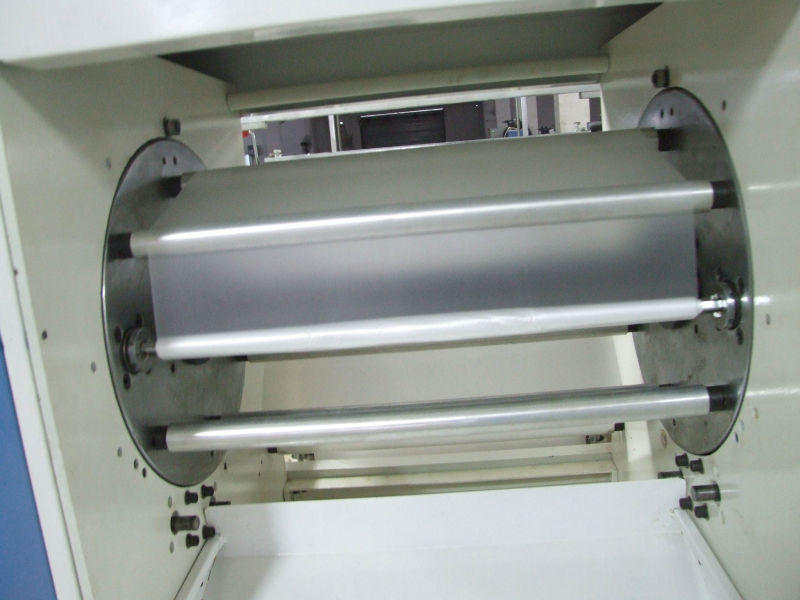

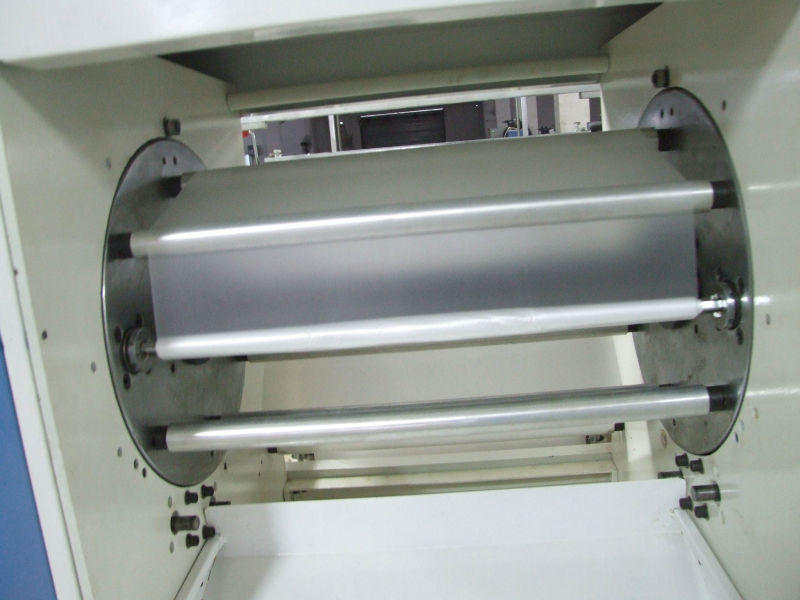

More machine pictures

|

Model |

FD800 |

FD1000 |

|

Producing Length |

400-1500mm |

400-1800mm |

|

Producing width |

800mm |

1000mm |

|

Rewinding width |

280mm |

320mm |

|

Producing Speed |

120pcs/min |

120pcs/min |

|

Total Power |

8.0kw |

9.0kw |

|

Film of thickness |

0.01-0.040mm |

0.01-0.040mm |

|

Weight |

1500kg |

1700kg |

|

Overall dimensions(L×W×H) |

5600×1800×2100mm |

5800×2000×2100mm |

�